Casing Magnetization

Contingency planned. Service delivered.

The Vector Magnetics Casing Magnetization Service is a cost-effective solution for increasing the detectable range of down-hole casing via Passive Magnetic Ranging methods. Whether as a contingency against a shallow blowout, to allow detection in extended salt formations where active ranging methods are ineffective, or to aid in well avoidance in densely spaced fields; Casing Magnetization provides an additional margin of safety at low cost and no risk to the wellbore.

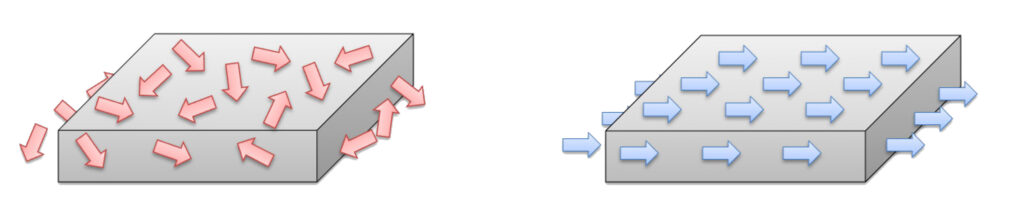

Passive Magnetic Ranging has been proven a technically sound, yet inconsistent method of locating existing casing strings, drillpipe, or other magnetic source materials downhole. This inconsistency is a result of the random distribution of magnetic domains within the un-magnetized material. In a normal string of unmagnetized casing these domains may arbitrarily align in such a way that near zero net magnetic signal is present above the background earth’s field. In such a situation Passive Magnetic Ranging is rendered ineffective, greatly complicating both the locate and follow stages of relief well drilling, making collision avoidance nearly impossible, and exposing stakeholders to excess risk.

Pre-magnetization eliminates this uncertainty by passing a select few joints through a portable electro-magnetic coil, magnetizing them to saturation and then installing them in a pre-defined pattern designed to maximize detection range. Prior to installation the final field strengths are measured and documented in a report and installation model provided to the customer to be included in the casing program.

The Casing Magnetization System is capable of handling casing of nearly any size, yet portable enough to ship via standard air cargo methods. Kits are based out of New York and Norway in partnership with AGR, and available for rapid deployment to customer sites globally.

Prior to magnetization the magnetic domains are random in distribution. Subjecting the material to a powerful electro-magnetic field forces all domains into alignment.

Requirements

- 220-250V AC 30 amp single-phase power

- Casing lifting equipment (fork truck, crane, etc.) and a dedicated operator.

Contingency

Shallow Blow Out

Shallow reservoirs present unique challenges in relief well design.

With limited TVD available to close the surface displacement between relief and target well locations, a high angle trajectory is required. Such an approach places any potential Active Magnetic source far above the relief well bottom and out of range for accurate locating of the blowing out well.

By magnetizing the shoe to the maximum possible field strength, a relief well may be drilled directly to intersect without the usual locate, pass-by, and follow phases of a traditional intersect plan.

Contingency

High Resistivity Zones

Highly resistive formations such as large salt deposits limit the efficacy of Active Magnetic sources in drilling a potential relief well.

Pre-magnetizing one or more sections of casing through this zone as a contingency enables the well to be located and followed to a successful intersection.

Vector Magnetics ranging specialists develop an installation pattern where the magnetic poles are varied to rise to maximum intensity at key points, maximizing detection distance while controlling cost by keeping the total number of magnetized joints low.

Contingency

Well Avoidance

Modern high angle directional drilling has sped the development of tightly spaced fields drilled from highly centralized locations.

Casing Magnetization offers a cost-effective method of further increasing density via the pre-magnetization of well casings whose positional uncertainties overlap.

As the overlap zone is approached, additional MWD surveys are collected as directed by Vector Magnetics engineers, the location of the crossing well is determined, and the driller is given the information required to maintain acceptable separation.